Perforated Metal Sheets: Versatile Solutions for Modern Applications

Perforated metal sheets have become an essential material in various industries due to their versatility, durability, and functionality. These sheets are crafted by punching holes, slots, or other patterns into metal surfaces, offering both aesthetic and practical benefits. Their widespread use ranges from construction and architecture to filtration, noise control, and even decorative applications.

This article explores the many facets of perforated metal sheets, including their types, manufacturing processes, applications, advantages, and factors to consider when choosing the right sheet for your project.

What is a Perforated Metal Sheet?

A perforated metal sheet is a thin sheet of metal that has been mechanically or manually punched with holes or patterns. These patterns can be functional, aesthetic, or a combination of both. The holes in perforated sheets can vary in size, shape, and density, depending on their intended use.

Common materials used for perforated sheets include:

- Stainless steel

- Aluminum

- Carbon steel

- Copper

- Brass

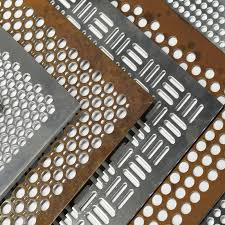

Types of Perforated Metal Sheets

Perforated sheets are classified based on their material, hole pattern, and intended application:

- Based on Material:

- Stainless Steel Perforated Sheets: Ideal for environments requiring corrosion resistance, such as marine or industrial applications.

- Aluminum Perforated Sheets: Lightweight and resistant to rust, making them suitable for decorative and lightweight structural uses.

- Carbon Steel Perforated Sheets: Known for strength and durability, often used in heavy-duty industrial projects.

- Brass and Copper Perforated Sheets: Commonly used for decorative purposes due to their aesthetic appeal.

- Based on Hole Patterns:

- Round Hole: The most common pattern, used for ventilation, soundproofing, and filtration.

- Square Hole: Provides a modern look, suitable for decorative and industrial purposes.

- Slotted Hole: Used in applications requiring better airflow or drainage.

- Custom Shapes: Designed for specific requirements, offering unique patterns for architecture or branding.

- Based on Usage:

- Industrial Perforated Sheets: Designed for strength and functionality, used in filtration, noise control, and reinforcement.

- Decorative Perforated Sheets: Focus on aesthetics, used in architectural facades, interiors, and art installations.

Manufacturing Process of Perforated Metal Sheets

Perforated metal sheets are manufactured through a precise and controlled process:

- Material Selection: The first step involves selecting the appropriate metal based on the intended use.

- Punching or Perforating: The metal sheet is passed through a perforating press, which punches holes or patterns into the sheet. Modern CNC machines ensure precision and consistency.

- Finishing: After perforation, the sheet is treated to remove burrs, enhance durability, and improve appearance. Finishing processes include powder coating, anodizing, and polishing.

- Customization: For specific applications, sheets can be cut, bent, or shaped to meet unique requirements.

Applications of Perforated Metal Sheets

Perforated metal sheets have diverse applications across industries:

- Construction and Architecture:

- Used in building facades, sunshades, and cladding for a modern aesthetic and functional design.

- Provides ventilation and natural light while maintaining privacy.

- Acts as a structural element in stairs, walkways, and partitions.

- Industrial Applications:

- Utilized in filtration systems for liquids and gases.

- Serves as noise-reducing panels in industrial and commercial spaces.

- Used in safety guards, sieves, and machinery components.

- Automotive and Transportation:

- Used in grills, exhaust systems, and ventilation panels.

- Provides lightweight yet durable solutions for vehicle components.

- Home and Office Interiors:

- Applied in decorative screens, room dividers, and furniture design.

- Used in lighting fixtures to create unique designs and patterns.

- Agriculture and Food Processing:

- Utilized in grain drying systems, food processing equipment, and storage bins.

- Ensures proper airflow and hygiene.

- Energy and Environment:

- Used in solar panel backing and windbreaks.

- Plays a role in water filtration and waste management systems.

Advantages of Perforated Metal Sheets

- Versatility: Suitable for a wide range of applications, from industrial to decorative.

- Durability: Offers strength and long-lasting performance, especially in harsh environments.

- Lightweight: Aluminum and other lightweight materials reduce structural load.

- Aesthetic Appeal: Customizable patterns and finishes enhance design possibilities.

- Functionality: Provides ventilation, soundproofing, filtration, and weight reduction.

- Sustainability: Many perforated sheets are recyclable, making them an eco-friendly choice.

Factors to Consider When Choosing a Perforated Metal Sheet

To select the right perforated metal sheet for your needs, consider the following factors:

- Material:

- Choose the material based on environmental conditions (e.g., stainless steel for corrosion resistance).

- Hole Size and Pattern:

- Determine the hole size, shape, and density based on the sheet’s purpose (e.g., filtration, decoration, or noise control).

- Thickness:

- Ensure the sheet’s thickness meets the strength requirements of the application.

- Finishing:

- Consider the finishing options for aesthetics and durability.

- Cost:

- Evaluate the cost based on material, customization, and quantity.

Conclusion

Perforated metal sheets are a vital component in modern industries due to their blend of functionality and aesthetics. Whether for industrial use, architectural design, or decorative purposes, these sheets provide a versatile and efficient solution.

Their wide range of materials, patterns, and finishes allows for customization to meet specific needs, while their durability and sustainability make them a cost-effective and eco-friendly choice. With their many advantages, perforated metal sheets continue to be an invaluable resource in various sectors.