What are the significant reasons for using the cold cutting machine?

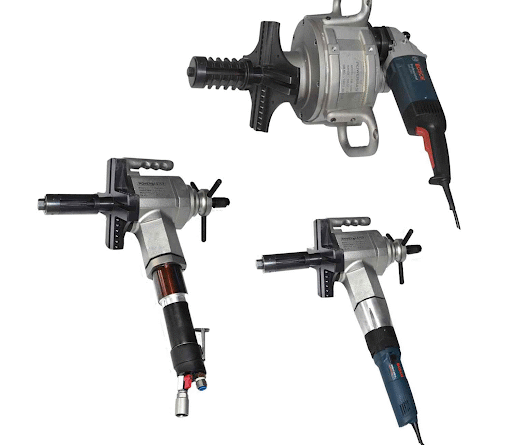

In many industries like power plants, oil and gas, shipbuilding and heavy engineering, precise and safe cutting operations are very important. Traditional techniques of cutting are very problematic in terms of generating the heat, sparks and much more, which leads to safety risk and damage to the material. This is where cold cutting machines will be playing a very important role because these are the advanced level technological Equipment that will allow you to cut through the metal without any production of heat or spark, and make it ideal for high-risk environments in industrial environments.

Benefits of using a cold cutting machine

- Helpful in promoting the safety: One of the significant benefits of using the cold cutting machine is the safety because it will never be producing any kind of flames, sparks or high heat which will make sure that chances of fire or explosion will be drastically deduced. This point will make it the preferred choice for the hazardous environment, which will include oil refineries and chemical plants.

- Very precise in terms of cutting: Cold cutting has been designed with the motive of providing you with clean and precise equipment and cuts without any issues. Unlike traditional cutting tools, there will be no chance of any kind of damage to the material or wrapping around due to excessive heat or any other related issues. Hence, using the cold cutting machine is a very good idea so that integrity will be perfectly maintained without any problem.

- No heat zone: One of the biggest possible issues with the thermal procedures was the creation of the heat-affected zone, which led to the weakness of the material around the cutting area. On the other hand, shifting the focus to a cold cutting machine is a very good decision because it will eliminate such issues and further ensure that the surrounding areas will be very well sorted out in terms of retaining the original strength and durability.

- Best possible variety and flexibility: The usage of the machine will be done in such a manner that it can perfectly cut through a good range of material, including steel, cast iron and pipeline of multiple thicknesses without any problem. Overall adaptability in all such cases will be making sure that suitability will be very well sorted out, and you will be able to enjoy the support factor in multiple applications. Pipeline maintenance and heavy machine repair will be done very well in the right direction without any problem in all such cases.

- Helpful in reducing the downtime: The cold cutting machine will always allow the worker to perform the cutting operations in the right manner without any shutdown of the entire system, specifically in the pipeline. This will help in reducing the downtime and will keep the operations running very smoothly, which will help in saving time and money.

Conclusion:

Apart from the points mentioned above, shifting the focus to the cold cutting machine is a very good decision because it will provide you with eco-friendly operations, and there will be no chance of any kind of wastage produced during the process. Hence, the cold cutting procedure will be much more eco-friendly in comparison to conventional cutting methods, which makes the decision to invest in cold cutting technology a very smart and cost-efficient decision.