The Advantages of Progressive Metal Stamping in Modern Manufacturing

Progressive stamping is a cutting-edge method for producing metal. By producing parts in large quantities, advanced die stamping benefits various sectors. Further machining is not required because only one tool is used throughout the operation. This approach makes for a better manufacturing venture because it enables production to happen much more quickly.

A key component of this process’s flow is individual workstations. Progressive stamping relies on a single process instead of other methods that call for conventional cutting and shaping. If the component is still linked to the stock strip, each workstation does a distinct part of the stamping process. Continue reading to learn the advantages of progressive metal stamping in modern manufacturing:

Both accuracy and precision

Precision metal stampings are expertly made by qualified, progressive metal stamping manufacturers. Specialized dies and advanced technology enable the production of metal components with reliable quality and accuracy.

Due to the dies’ precision cutting and shaping capabilities, stamped items can have small deviations and strict tolerances. This level of accuracy is necessary for industries that require high-end components, such as electronics, aerospace, and automobiles.

Professional manufacturers are able to fulfill this industry’s tight needs and demands. They that the stamped components perform as intended with the use of metal stamping tool and die.

Quick Production:

Skilled metal stamping manufacturers offer progressive and die-stamping procedures to quickly mold sheet metal into various shapes. Comparing large-scale manufacturing of comparable parts to alternative processes such as CNC machining or welding may significantly reduce overall production time.

Automation and control approaches also support enhanced efficiency by making the process more inexpensive overall while preserving speed by enhancing speed, reducing labor costs, enabling quick die-changing systems, etc.

Design Flexibility:

Expert metal stamping manufacturers can also optimize the functionality of their products because they have more creative freedom in design. To enhance the look and performance of the stamped item, they can add features like texturing, debossing, and embossing.

Manufacturers can create components that exactly match their product concept with the help of metal stamping services.

The cost-effectiveness

Metal stamping is a cost-effective method of producing complex components. It requires less labor, less machinery, and less secondary expenses. Automating the metal stamping system reduces engineering time and effort, so there will be significant cost reductions.

Compared to alternative metal shaping techniques, this method yields superior quality results faster without sacrificing accuracy. So, it is a better choice that also yields financial gains.

In what sectors does metal stamping have the greatest advantages?

Metal stamping is a great solution in many industrial sectors for precise manufacture at an affordable price. This metal technique is accurate and versatile, benefiting industries such as electronics, automotive, aerospace engineering, and medical device manufacturing.

Different Metal Stamping Types

Progressive, four-slide, and deep draw are the three main categories of metal stamping processes.

Progressive Die Stamping

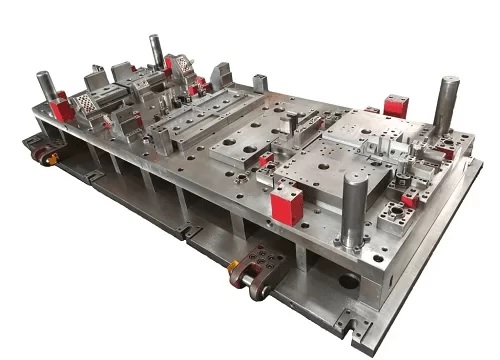

There are several stations in progressive die stamping, each with a specific purpose.

A progressive stamping press is first used to feed strip metal. After the strip is gradually unrolled from a coil, it enters the die press, where it is chopped, punched, or bent at each tool station. Parts are finished when the acts of each subsequent station build upon the work of the preceding stations.

A single manufacturer might have to invest in several presses, each doing a specific task required for a completed component, or they might regularly need to replace the tool on a single press. Additional machining services were often required to complete a product fully, even with numerous presses. Progressive die stamping is the best option for metal items with intricate geometry that must satisfy certain requirements.

Fourslide Stamping

Fourslide, also known as multi-slide, is a process that uses four slides and horizontal alignment. In other words, the workpiece is shaped by using four tools at once. This procedure can develop even the most complex elements by making delicate cuts and complex bends.

Compared to conventional press stamping, four-slide metal stamping has several benefits that make it the better option in many situations. Several benefits include Flexibility for more intricate parts and adaptability for design modifications.

Deep Draw Stamping

In deep drawing, a sheet metal blank is formed into a shape by being pulled into the die with a punch. The process is called deep drawing when the drawing part is deeper than its diameter. Compared to turning techniques, which usually involve using more raw materials, this form of forming is more economical and suitable for producing components requiring multiple series of diameters.

Final words:

Businesses may increase production by using metal stamping presses to produce huge quantities of parts quickly and affordably. Further savings are possible because progressive metal stamping often requires less money and maintenance than other procedures.